Anti-explosion equipment is an important part in industrial environments such as refineries. Failure to use this equipment in hazardous industrial environments can cause explosions and fires. Explosion-proof equipment must pass tests before use to confirm their standard. Non-standard explosion-proof equipment has no value. The ATEX standard is one of the most reliable explosion-proof equipment standards in Europe.

What is the ATEX standard?

ATEX stands for Explosible Atmosphere. ATEX is a European standard for explosion-proof electrical or mechanical equipment and systems. This equipment is used in high risk areas. High-risk areas are areas where there is a possibility of fire and explosion due to the presence of flammable gases, liquids or dust. For this reason, explosion-proof equipment should be used in such areas.

In industries and environments prone to explosion, the use of ATEX approved equipment is very important to protect and prevent explosions related to the equipment. The explosion-proof equipment must have technical requirements for the types of areas used. ATEX standard by European guidelines And special equipment signs are set.

To learn about explosion-proof equipment, you can read the following article:

Directive 99/92/EC or ATEX 137

The owners of high-risk industrial businesses are obliged to assess the risks of explosion and take the necessary measures to eliminate or reduce these risks:

- Assessment of explosion risks on your site

- Classification of dangerous areas and presentation of signs

- Keep an explosion protection document

- Carrying out preventive technical and organizational measures

- Compliance with the selection criteria of electrical equipment

Directive 2014/34/EU (reissued 94/9/EC) or ATEX 95

Responsibilities of the manufacturer of anti-explosion equipment are:

- Requirements for protective equipment and systems intended for use in explosive atmospheres (eg gas detectors)

- Requirements for safety equipment and controls intended for use outside of potentially explosive atmospheres but required for the proper operation of protective equipment and systems (such as controllers).

- Classification of equipment groups into categories

- Essential health and safety requirements related to the design and construction of equipment or systems

How is the zoning of dangerous areas in the ATEX standard?

According to the ATEX standard, explosion-proof equipment is divided into two groups and || They are divided, group I is divided into categories M1 and M2 and electrical equipment of group II is divided into categories 1, 2, 3.

- The first group: are anti-explosion equipment that are used in underground mines such as coal mines and their connection facilities to the ground surface are exposed to flammable gases such as methane and dust.

- The second group: are anti-explosion equipment that are used in areas other than mines and may be exposed to flammable gases and substances.

| Anti-explosion equipment group | Grouping | degree of protection | explanation |

|---|---|---|---|

| | | M1 | very high | This electrical equipment is used in underground facilities and mines where methane (flammable gases in mines) and coal dust may be present. These equipments are in working mode in the presence of flammable gases and dust. |

| || | M2 | top | This category of electrical equipment is used in underground facilities and mines where methane (flammable gas in mines) and coal dust may be present. These explosion-proof equipment must be turned off in the presence of flammable gases and dust. |

| || | 1 | very high | This category is explosion-proof electrical equipment for use on the ground. Flammable gases, mists, vapors and dusts may be present in these environments. This equipment can continue to work in zones 1, 2, 3, 20, 21, 22. |

| || | 2 | top | This category of electrical equipment is suitable for use in areas where there is a possibility of flammable gas, fog, steam and dust. This equipment can continue to work in zone 1, 2, 21, 22. |

| || | 3 | Normal | This electrical equipment is suitable for use on the ground where there is a possibility of gas, fog, steam and flammable dust. These equipments can continue to work in the areas of Zone 2, 22. |

The zoning of hazardous environments prone to the presence of flammable gases and dusts in the Atex standard is as follows:

| gases | dust | explanation |

|---|---|---|

| ZONE O | ZONE 20 | An environment where flammable materials are present for a long time and more than 1000 hours per year. Electrical equipment is not installed in these environments. |

| ZONE 1 | ZONE 21 | An environment where there are volatile and flammable substances. The time of existence of these materials should be between 10 and 1000 hours. |

| ZONE 2 | ZONE 22 | An environment in which there is no flammable under normal conditions, but there is a possibility of leaking explosive materials in a short period of time between 1 and 10 hours per year. |

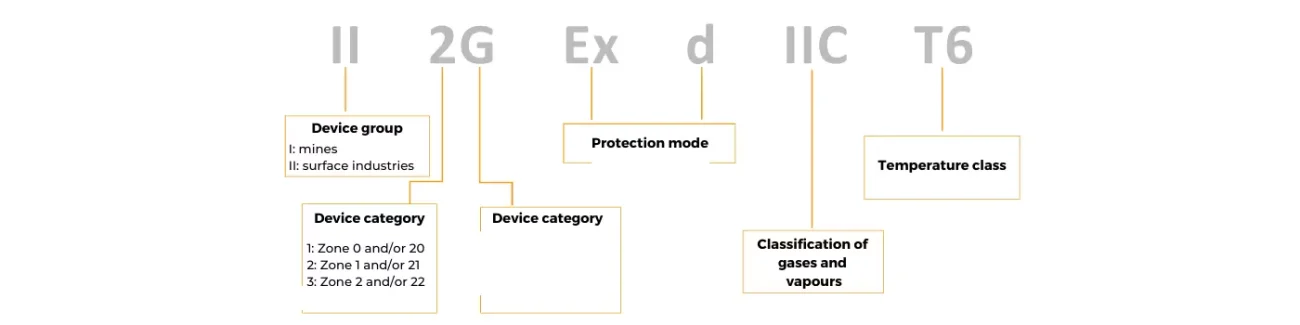

ATEX equipment marking

Article 137 of the ATEX Directive 99/92/EC defines the responsibilities of employers regarding the use of equipment designed for explosive atmospheres:

- Preventing the formation of explosive atmospheres

- Avoid ignition of explosive atmospheres

- Reduce the effects of the explosion

| Expressions in the Atex standard | The meaning of terms in the Atex standard |

|---|---|

| || | Suitable for mines or other industrial environments |

| 2 | Equipment category |

| G | Gas or dust |

| EX | Explosion protection |

| d | Type of protection |

| C|| | Level of protection |

| T4 | Temperature class |

| Gb | Ultimate safety |

The ATEX certification and standard is granted to equipment that has passed the rigorous tests specified by the European Union directives. Products that have an ATEX certificate are intended for use in specific environments with explosive atmospheres, depending on the area or areas for which the certificate of use is used. Any product that has received ATEX certification has the official “Ex” mark, indicating that they are safe in an explosive atmosphere.