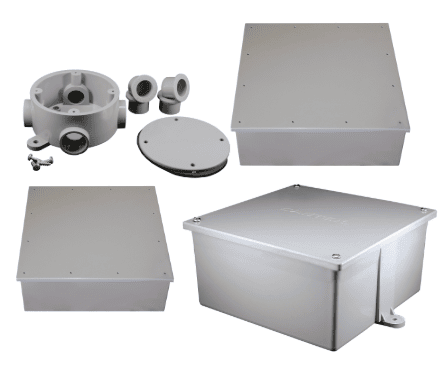

Junction boxes are an essential part of electrical wiring systems for homes, buildings and industries. These metal or plastic boxes house the electrical connections of the structure and protect it safely. These electrical enclosures are produced in different sizes and types. In the following, we will tell you completely what is a junction box?

What is a junction box? And what is its use?

The junction box is used to branch wires and cables or connect them to each other. In addition to its appearance, the junction box provides a safe and protected place for electrical connections. These distribution boxes are usually used in wall plaster, ceiling or in concrete and according to your needs, they are made of different materials. But in industrial systems, an explosion-proof junction box is used, which usually exposes it in an accessible place.

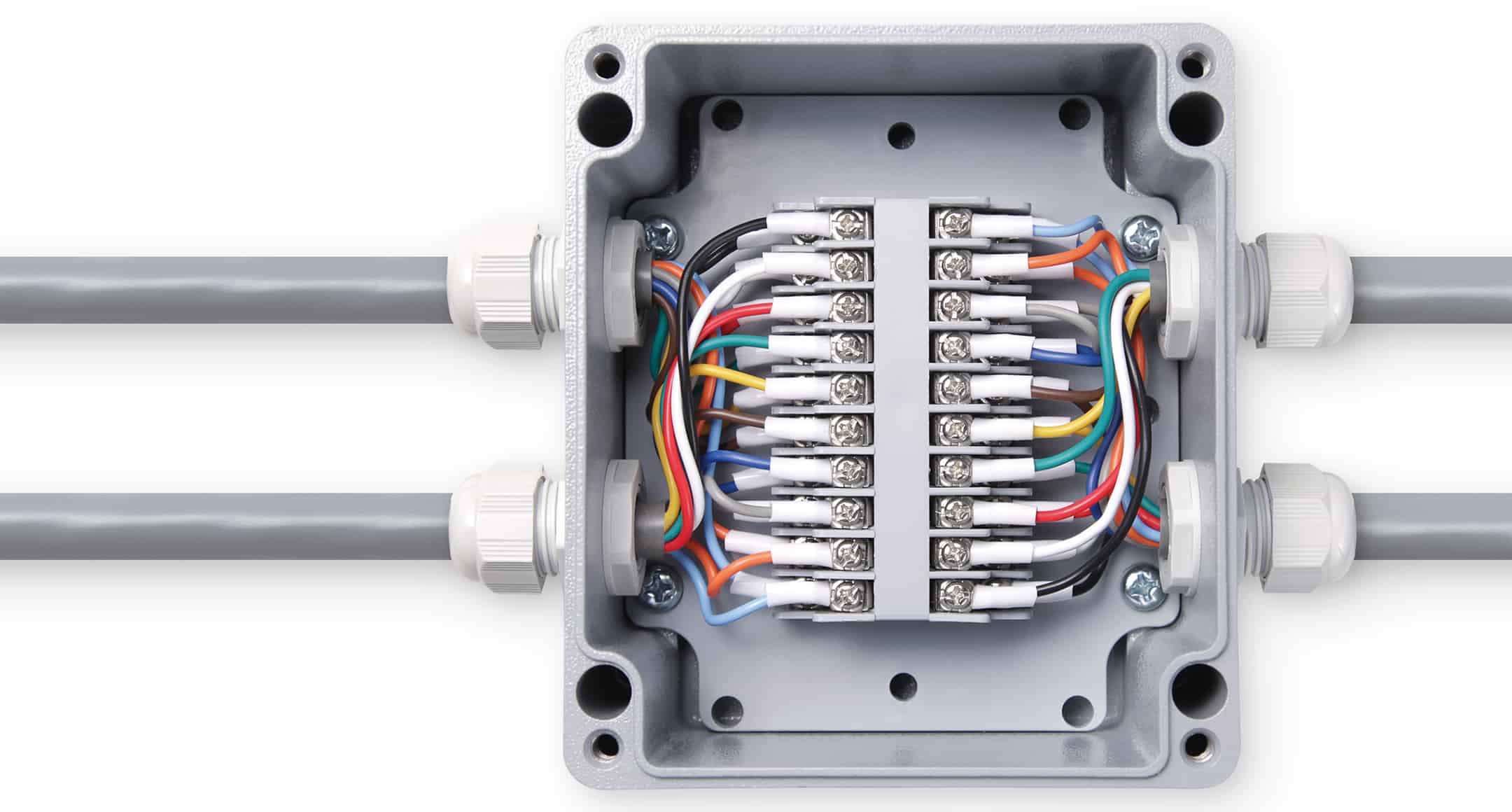

The junction box acts as a common junction for electrical wires, where they are connected to each other before running. These boxes protect the hot (black), white (neutral), and ground (green or copper) electrical wires and may contain some other wire colors for secondary functions and lighting.

A sheathed ROMEX wire (ROMEX is a brand name for electrical wires with a non-metallic sheath) runs from the main panel or a subpanel to the junction box. The wires are connected to the Romex main wire and distributed to other fixed boxes. In this process, all wire gauges (wire diameter size) must be the same.

Junction boxes protect the wire covering, remove dirt and dust and prevent moisture from entering the box. They also prevent ignition of combustible materials in the event of arcing due to a loose connection or short circuit. prevents.

Almost every modern electrical system requires a junction box or junction box. However, commercial electrical systems are often subjected to more severe conditions than residential systems. For commercial applications, it is important to specify junction box models that are built to stricter standards and equipped with commercial features.

Benefits and use of junction box:

- They protect people from contact with electric wires.

- Protects used wires from dust and moisture.

- It prevents the wire from being chewed by small rodents (mice).

- Organization of the electrical map of the building in several units

- It prevents fire from spreading inside the distribution box.

- Connection boxes have the ability to install explosion-proof glands.

- The presence of rail terminals in junction boxes makes it easy to connect two or more wires or branch off one wire.

In general, junction boxes prevent environmental damage such as water, mice and people to the wires. If properly covered, it will prevent a fire that started inside the distribution box from spreading to the outside. In addition, distribution boxes help to simplify electrical wiring inside the building.

Each junction box in a building represents a different part of the building’s wiring diagram. Larger distribution boxes can also provide surge protection for the entire building. This kind of organized layout makes doing any kind of electrical work much easier (just like getting the most out of a good set of power tools). If there was no distribution box, the electrician’s work would be much more difficult.

Junction boxes or distribution boxes are used to increase safety in residential buildings and explosion-proof junction boxes are used to increase safety and prevent fire and explosion in industrial and explosive environments.

Types of explosion-proof junction boxes by gender

- Stainless steel junction box

- Explosion-proof aluminum electrical distribution box

- GRP explosion-proof junction box

- Plastic junction box (PVC):

Explosion-proof stainless steel junction box

The explosion-proof junction box is made of stainless steel and is suitable for use in electrical installations. These explosion-proof boxes can be used in wet and aggressive environments as well as in environments that contain corrosive substances. is used

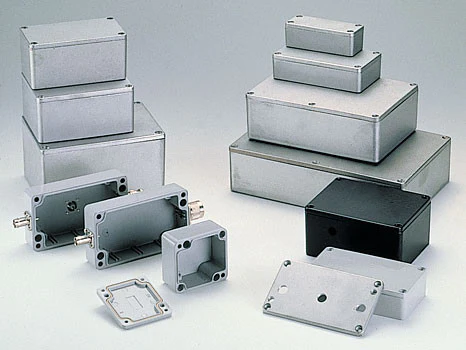

Aluminum junction box

Aluminum junction box is lighter in weight and has better corrosion protection compared to mild steel junction boxes. However, aluminum is not as durable as steel and corrosion may occur in environments where conditions are favorable.

The explosion-proof aluminum junction box has a high degree of protection against water and dust and is suitable for starting electrical equipment in industrial and high-risk environments.

GRP explosion-proof junction box

Explosion-proof junction boxes are produced with GRP material reinforced with polyester and fiber optics. This model of explosion-proof junction box is suitable due to its high resistance to fuel oil pollution, mechanical and physical shocks, lightness and practicality. For use in all kinds of factories and industrial environments that are prone to explosion. GRP partition boxes are designed and produced in various thicknesses, sizes and shapes.

Plastic junction box (PVC)

PVC distribution box is also known as PVC electrical box. PVC (polyvinyl chloride) partition boxes are very popular and for good reason. PVC is light, cheap and strong. PVC is a non-conductive material. As a result, if your PVC junction box comes into contact with a bare wire, fixture or switch (in the event of a fault), it will not conduct electricity (it is not conductive). For this reason, there is no need to connect the PVC distribution boxes with the base to the ground. You can easily staple it to the holes in the back or sides of the PVC electrical distribution box. In addition to being light, the PVC junction box is very simple to install, set up and operate.

junction box made of ABS (plastic)

ABS junction box is also known as ABS electrical box. ABS (acrylonitrile-butadiene styrene) is a hard, strong, easily adjustable and inexpensive plastic. It is very similar to PLC and compared to materials such as metal and fiberglass, it has many advantages and disadvantages.

The differences between PVC and ABS junction boxes:

- ABS is able to withstand colder temperatures and its impact resistance will be slightly higher.

- PVC is a little cheaper and has little UV resistance.

- ABS has the same chemical resistance as PVC. ABS, like PVC, is a non-conductive material. As a result, there is no need to ground the ABS junction box with the base.