A2RC Cable gland

ade-1fc cable gland

BIMED anti-explosion gland

CABLE GLANDS ARMOURED CGA (ZONE 1 AND 2)

CABLE GLANDS UNARMOURED CG (ZONE 1 AND 2)

CMP anti-explosion gland

EXACAP Ex e and Ex i explosion-proof cable gland

Gland Cable 501/453/Universal

TMC armor gland

Anti-explosion gland

Anti-explosion gland is one of the anti-explosion equipment that protects the cable and its connection point to the distribution box from possible dangers in dangerous areas. Or the electrical panel enters.

Anti-explosion glands are designed and built to prevent the explosion inside the enclosure and to prevent the ingress of flammable gases or vapors from dangerous places to electrical equipment.

Construction of explosion-proof Gland

For the production of explosion-proof glands, materials are used that can withstand the harsh and dangerous conditions that exist in industrial and explosive environments and prevent accidents. The materials used in the production of explosion-proof glands must have the following characteristics. be:

- High resistance to heat

- Pressure resistant

- UV resistant

- Resistant to chemicals

Metals such as steel, aluminum and copper are used in the production process of the explosion-proof gland and its insulation, and to prevent sparks and explosions, parts for electrical discharge are used inside the explosion-proof gland, which are made of metals such as brass. or aluminum.

The use of electrical discharge parts in explosion-proof glands is used as a safety solution to reduce the risk of sparks and increase safety in dangerous and explosive environments.

The components of the anti-explosion gland

- Stabilizer nut

- Sealing washer

- Cable protective washer

- Body and fork holder

- cap

What is the use of anti-explosion gland?

As it was said, the anti-explosion gland is one of the anti-explosion equipments, which aims to protect people and equipment against possible explosions in dangerous places such as gas, oil, petrochemical industrial plants and all kinds of sensitive industries where electrical tools and equipment and the environment are in They are prone to explosion, it is used. (These areas are based on the type of flammable material and the possibility of its release to create an explosive atmosphere)

In addition to keeping the end of the cable firmly on the distribution box and also protecting it against environmental factors, explosion-proof glands prevent the penetration of flammable gases, particles and dust into them.

Note that a cable can potentially explode for a number of reasons:

- Destruction of insulation

- Overload

- short circuit

- Physical damage

- Environmental factors

- Poor installation

It is for these reasons that it is necessary to use anti-explosion gland in dangerous and explosive environments.

In what environments is the anti-explosion gland used?

- Power flow control and generation systems

- Production and transmission centers of gas and petroleum compounds such as

- petrochemicals, refineries, oil and gas companies, etc.

- Instrumentation systems

- Companies and centers that deal with flammable pollutants

- Machine tool systems and factories that produce automatic devices

- Explosives production companies

- Energy production factories

The steps of installing an explosion-proof gland

Anti-explosion glands are used in environments that are constantly exposed to explosion due to the presence of flammable gases and vapors. For this reason, one should be careful in installing the anti-explosion gland and install it in the environment according to standard methods. Installed.

Tools required for Gland installation: cable cutting tool, screwdriver, pipe and candle.

- Choosing the right gland: In the first step, you must choose the appropriate anti-explosion gland for the required cable. For this, you should pay attention to the size and diameter of the desired cable and choose and buy a suitable size gland.

- Cutting the cable: in the second step, you must cut the cable with a suitable size for the gland. To cut the cable, use special tools for cutting the cable.

- Gland Installation: Add the explosion-proof gland to the cable and connect it to the electrical box.

- Installing the gland to the pipe: in the next step, connect the gland to the pipe and place it inside the electrical chip.

- Attaching the gland to the chip: Using a screwdriver, attach the gland to the electrical chip. Do this carefully so that the gland is completely and firmly attached to the electrical chip.

- Testing the gland: In the last step, it should be tested to ensure the proper functioning of the gland. Open the gland and check from inside that the cable is installed correctly and that no part of it is compressed by the gland.

Types of anti-explosion glands

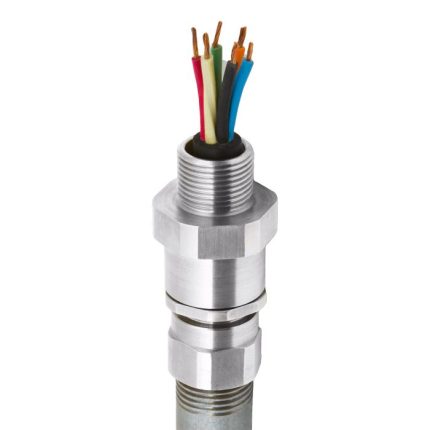

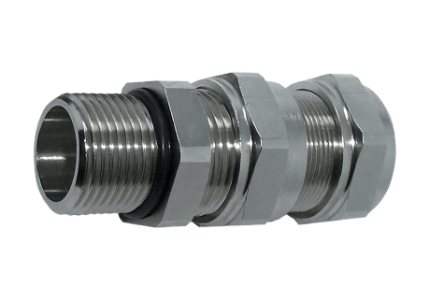

Anti-glands are produced and designed in two models, armored and non-armored. Armored Gland and Unarmoured Gland are two different types of glands that differ from each other in terms of outer covering.

The code 453 on the anti-explosion glands indicates that the gland is armored, and the code 421 indicates that the anti-explosion glands are not armored.

| Gland model | Description |

|---|---|

| Armored Gland | Armored glands have a protective layer against damage and have types of single-wire armor, woven armor, flexible armor, and armor with double and steel strips. These types of glands are used in environments that are exposed to loads and damage. mechanical and physical are located, it is used. |

| Gland without armor | Glands without armor have a relatively simpler structure than armored glands, and there are types without sealing, with one external sealing layer or two external sealing layers. These types of explosion-proof glands are used when Equipment and cables should not be exposed to mechanical damage. |

Types of anti-explosion glands in terms of sex

- Anti-explosion gland with stainless steel material

-

Plastic explosion-proof gland

- Aluminum anti-explosion gland

- Explosion-proof brass with nickel plating

- Anti-explosion gland with PVC material

Types of anti-explosion glands in terms of size

The size of explosion-proof glands is selected based on the diameter of the cable. Electric cables have different sizes. Explosion-proof glands are also produced in different sizes so that they can be used on different sizes of cables.

- Armored and non-armored explosion-proof Gland size M12 to M100

- Explosive armored and non-armored glands size PG11 to PG63

- Armored and non-armored explosion-proof glands, size 1/4 inch to 3 inches

The degree of protection of the anti-explosion gland

- IP 67: Glands with IP 67 degree of protection are waterproof and have long-term resistance and durability in harsh weather conditions. They are also well protected against dust and withstand immersion in water between fifteen centimeters and one meter for 30 minutes.

- IP 68: These explosion-proof glands with IP68 protection grade have the highest waterproof properties and are able to completely prevent dust from entering. It is worth noting that these glands can be under pressure continuously and for a long time.

- IP 69: explosion-proof enclosures with IP69 degree of protection have the property of protecting against high-pressure water, high temperature and dust. This type of explosion-proof enclosures is suitable for use in sensitive distribution boxes and devices that require water. They have a clause.

Paying attention to these points is very important for buying anti-explosion equipment, including anti-explosion glands. You can contact our consultants to buy suitable equipment.

For more information about all types of explosion-proof equipment and instrumentation equipment, you can visit the website of Parsa the ex poroof and get in touch with the consultants.

Dubai office: 0568410575

Persian language support Phone: +989351556085