Anti-explosion equipment prevents the occurrence and creation of explosions in high-risk places that are prone to explosion due to the presence of flammable gases, vapors and dust.

8150 series stainless steel explosion-proof box (Ex e junction box)

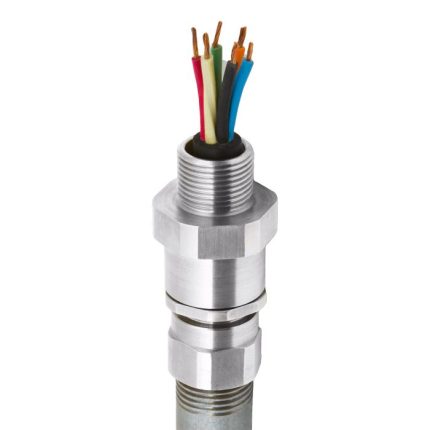

A2RC Cable gland

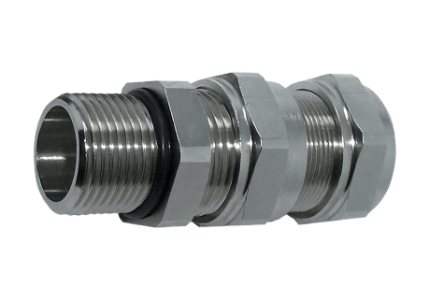

ade-1fc cable gland

Aluminum junction box – JBE1

Anders Hauser level transmitter FMX167 series

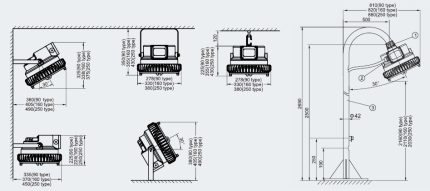

Anti-explosion fluorescent Warom EX BAY51-Q

Appleton explosion-proof distribution box

BAD anti-explosion lamp

BDD95 explosion-proof lamp

BIMED anti-explosion gland

CABLE GLANDS ARMOURED CGA (ZONE 1 AND 2)

CABLE GLANDS UNARMOURED CG (ZONE 1 AND 2)

Anti-explosion equipment

Anti-explosion equipment refers to devices that are designed to prevent the explosion of gases, toxic substances, flammable dust, etc. Ex stands for explosion-proof equipment.

In high-risk industrial places and environments, any kind of electric current, such as creating a spark due to contact with an electrical connection, can cause the ignition of combustion fluids and the occurrence of irreparable explosions. They prevent leakage of electric current to the outside of the enclosure, and there will be no possibility of leakage of liquids, dust and flammable gases inside this equipment.

Any type of equipment that is protected against the ingress of dust, water and flammable liquids is classified as explosion-proof equipment. The body of this equipment is insulated against any type of electric current. Therefore, there is no possibility of spark penetration from inside this equipment.

Anti-explosion equipment is used in these environments:

- Petrochemical and nuclear plants

- Refineries and mines

- Oil and gas tanks

- Oil rigs

- Gas stations and CNG stations

- Labs for manufacturing medicinal alcohols

- Laboratories working with chemicals, especially alcohol production

- Paper and paint warehouses

- Work houses and many industrial environments

- Chemical factories

Introducing various types of anti-explosion equipment

Any tool or device that has EX standards is considered as explosion-proof equipment. Explosion-proof equipment has different categories. From lights or explosion-proof boxes to explosion-proof mobile phones or explosion-proof cables. All explosions are anti-explosion equipment.

Explosion-proof boxes

- Explosion-proof junction box

- Explosion-proof terminal box

- Explosion-proof panel

- Explosion-proof distribution box

Explosion proof lamp

- Explosion-proof moonshine

- Explosion-proof pendant light

- Explosion-proof projector

- Explosion-proof flashlight

- Explosion-proof tunnel light

- Explosion-proof hand light

- Anti-explosion signal light

- Explosion proof exit light

Explosion-proof fittings

- Anti-explosion glands

- Explosion-proof cap

- Explosion proof conversion

- Flexible explosion-proof

Explosion-proof keys

- Explosion-proof socket and plug

- Explosion-proof socket box

- Anti-explosion key

- Explosion-proof limit switch

- Explosion-proof push button

Anti-explosion warning equipment

- Anti-explosion alarm

- Anti-explosion flasher

- Explosion-proof mast light

Explosion-proof ventilation equipment

- Anti-explosion fan

- Explosion-proof cooler

Explosion-proof telecommunication systems

- Explosion-proof telephones and radios

- Anti-explosion control systems

- Industrial process control equipment

- Explosion-proof telephones

- Automatic monitoring and control

Explosion-proof energy transmission and distribution systems

- Explosion-proof cables

- Anti-explosion diesel generator systems

- Power transmission and distribution equipment

Anti-explosion equipment standards

The most important point before buying explosion-proof equipment is to pay attention to the standard and valid certificates of the equipment. Explosion-proof equipment must have EX standards. Manufacturers of explosion-proof equipment all over the world must receive EX standards for their products. Otherwise, their products will not have any validity.

To buy anti-explosion equipment, you must be familiar with various standards and codings and buy this equipment according to your needs.

Anti-explosion equipment standards are written on the equipment with a combination of English letters and numbers. These letters and numbers have special meanings for each of the standards.In the coding of anti-explosion equipment standards, after the abbreviation of anti-explosion equipment (EX), codes including numbers and letters are inserted. These codes represent the installation environment, type of protection, gas classification, thermal class, operation methods, etc. These codes can vary based on the type of standards.

Valid standards of anti-explosion equipment

- European explosion-proof directives (ATEX standard)

- Non-explosive regulations in the United States and Canada (NEC)

- European explosion-proof equipment standard (IEC)

- EN standard

Zoning of dangerous areas and anti-explosion equipment

If you look on the body of anti-explosion equipment, you will see words and numbers such as ZONE 1, ZONE2, or EXD, EXP, etc. These words are actually the classification of dangerous areas. Knowing this information, you can Check the technical aspects of installing equipment in dangerous environments. Pay attention to this point and pay attention to the classification or zoning of dangerous areas before buying explosion-proof equipment.

According to the NEC standard of the United States of America, hazardous areas are classified into three classes, each of which is divided into two divisions.

| CLASS 1 | Class 1 places include areas where there may be gases, vapors or liquids that have a high ignition potential. Places that are considered class 1 include oil refineries, gasoline storage areas, fuel service areas, etc. .are. |

| CLASS 2 | This class includes places where there is a possibility of the presence of combustible dust that has the potential to ignite. These places include grain elevators, flour and feed factories, metal powder manufacturers and coal factories, etc. |

| CLASS 3 | There are places where there may be fibers that have the potential to become flammable. These places include cotton gins, cotton seed factories, sawdust factories, or textile factories, etc. |

According to the IEC 60079 standard, dangerous areas prone to the presence of flammable gases are divided as follows:

| ZONE | Risk level | explanation |

|---|---|---|

| ZONE0 | very high | In this area, there is a mixture of flammable gases and air more than 1000 hours per year (on a sustained basis). |

| ZONE1 | medium | In this area, flammable gases are present between 10 and 1000 hours per year under normal conditions. |

| ZONE2 | Low | In this area, there is a mixture of flammable gases less than 10 hours a year and with a low probability of gas leakage. |

According to the IEC 60079 standard, hazardous areas prone to the presence of flammable dust are divided as follows:

| ZONE | Risk level | explanation |

|---|---|---|

| ZONE20 | very high | In this area, flammable dusts exist permanently or most of the time. |

| ZONE21 | medium | In this area, there are small amounts of flammable dust under normal conditions, which can cause fire and explosion. |

| ZONE22 | Low | In this area, inflammable dusts are very few and rarely present or in a very short period of time. |

Introduction of anti-explosion protections in electrical equipment:

- EXD anti-explosion equipment: these equipment can withstand the explosion of flammable gases or vapors without igniting or damaging the surrounding environment.

- EXP anti-explosion equipment: These are anti-explosion equipment whose air inside the chamber has been emptied or filled with neutral gases. In this way, any kind of spark and electrical connection cannot leak out of the chamber.

- EXe anti-explosion equipment: This type of protection has a double degree of safety, such as thermal stability and preventing the spread of sparks. The EXe protection level is designed and created to prevent leakage of electric arc current. The housing of these explosion-proof equipment is often made of stainless steel or GRP material.

- EXDE anti-explosion equipment: There are equipment in which the spark-generating and non-sparking parts are separated. Sparking parts are placed in class d explosion-proof enclosure and non-sparking equipment is placed in class e enclosure. The whole set creates an EXDE class explosion-proof electrical unit.

- Ex i: Inherent safety

- Ex p: Protection related to pressurized containers

- Ex q: Protection related to powder filled equipment

- Ex o: Protection of equipment through immersion in non-flammable liquids

- Ex nA: Protection related to spark-ignition equipment

- Ex nC: Protection related to enclosed sparking equipment

- Ex nR: protection related to the confined space to prevent the entry of flammable gases and vapors

- Ex m: Equipment protection by encapsulation

- Ex t: Equipment protected against flammable dust

The price of anti-explosion equipment

The price of anti-explosion equipment can vary depending on various factors.

Factors such as:

- Type of anti-explosion equipment

- Manufacturing Country

- Manufacturer brand

- Materials used in production

- Protection grade

To know the price of explosion-proof equipment and instrumentation equipment , you can contact our consultants on the Parsa the ex proof website.

Persian language support Phone: +98935155608

English and Arabic language support WhatsApp: 00971568410575

English and Arabic language support telegram: +16026522982