ABB field mount temperature transmitter

ABB field mount temperature transmitter

ABB field temperature transmitter is one of the most durable and reliable equipment in the field of instrumentation and can be used in a variety of industrial processes.Anders Hauser level transmitter FMX167 series

DURAVIS linear valve control

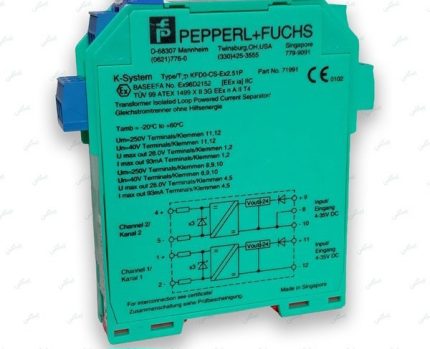

PEPPERL+FUCHS explosion-proof safety barrier

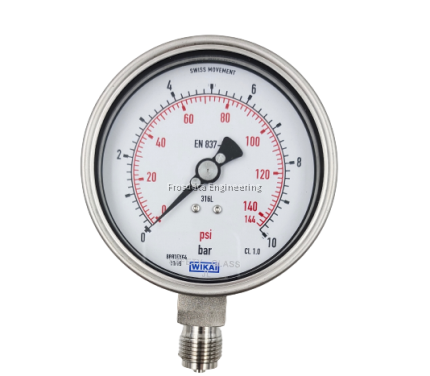

pressure gauge WIKA 10bar/140 psi

Rosemount pressure transmitter model 1151

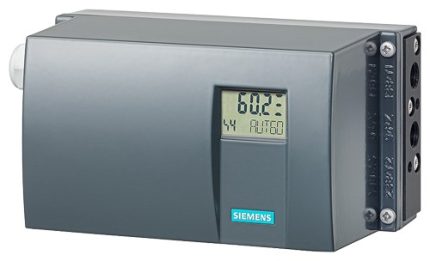

Siemens SIPART PS2 electro-pneumatic positioner

Simtronics DM-TX6-X gas detector

Simtronics methane gas detector model GD10

Valbia pneumatic actuator

accurate tool equipement

Today, the use of precise tools in various industrial projects is necessary and very practical. In fact, precise tools are a very important part of every industrial project, and it is impossible to imagine an industry without the use of precise tools.

Instrumentation is a general term for introducing measurement tools that are used to measure, control, record and display physical values in various industries. In every industrial process, a number of physical and chemical parameters are required to be continuously monitored and be controlled The process of knowing and controlling physical and chemical parameters in industries can only be done using the science of precision instruments.

By using precision instrument equipment, various quantities such as temperature, pressure, flow, fluid level, gas concentration, PH values, etc. can be measured with the least amount of error and in the most accurate way possible. Pay attention to this point. In industrial environments, all these parameters must be measured first and then controlled.

In other words, it can be said that precision instruments are equipment that are used according to the type of quantity required by the unit under control, including pressure, temperature, flow rate, surface and according to the existing conditions and standards. Instrumentation engineering It is a science that deals with the measurement and control of physical quantities such as pressure, temperature, material level in tanks, flow, etc.

What are the applications of measuring systems and instruments?

- Process monitoring: The basic task of measuring devices and instruments is monitoring. For example, an ammeter that shows the amount of current or voltage in a circuit is responsible for monitoring.

- Process control: Another application of measuring devices and instrumentation equipment is the automatic control of systems. In order to control the variables of a process such as temperature, pressure, level and intensity of flow, it is necessary to measure them at the desired points.

- Statistical analysis of engineering problems: To solve engineering problems, using statistical methods based on experimental data is more useful and appropriate than analytical methods. To solve some statistical problems, to obtain experimental data, measured data is used. can be

Instrumentation equipment working method

The performance of instrumentation equipment is that the transducer converts physical quantities such as speed, force or temperature into electrical quantities using one or more types of sensors. These electrical quantities include electrical resistance, are voltage or electric current. For example, a resistance strain gauge (Strain Gauge) converts the change of relative length in an object into a change of resistance. This change of resistance is converted into voltage by means of electric circuits.

In the later stages of this process, based on the standard voltage value of the system, the output voltage from the improvement circuit section is entered into the amplifier to reach a standard value. Then, it is transferred to digital recorders for monitoring or controlling the process. And it will be exposed to you by the available monitors.

All kinds of instrumentation equipment

Sensor

Sensors are devices that are capable of measuring and converting physical quantities into electrical ones. A sensor measures temperature and converts it into an electrical signal.

transmitter

Transmitters are equipment that measure (sensor), convert and amplify signals in one set. Transmitters or transmitters are equipment that have many uses and benefits in large processes in various industries, because the distance of the transmitters from the room There are many controls and only using the transmitter can be a good choice.

Transducer

Transducers are actually responsible for converting the output signals of the sensors into standard signals. For example, using a thermocouple with outputs of millivolts in various industries is completely wrong, because in these cases, a thermocouple converter can be used to signal 0-10 volts. In general, it should be said that transducers are They act as a converter.

Display

Displays are used to display the value of measured parameters of precision instruments.

For example, to display the pressure value of a sensor or the temperature value measured by the sensor, you must use displays that support the same sensor or standard inputs such as 0-10 volts, 4-20 mA.

controller

The controller is an electronic circuit that is used to control input and output values. Based on the measured values, the controller controls the system and sends predefined commands to advance the process.

The final element

The last stage of any process is called the final element (of course, if it is a control process). Of course, this final element can be different in different processes. It is possible that in a process, the final element is a control valve or in a process It is an electric motor, in another process it is pneumatic and hydraulic jacks and...

It can be said that operators are the final element.

Actuator

The actuator converts the control signal into a physical signal in order to control the process.

Positioner

Positioner is a device that is installed and used in connection with the control valve and for its adjustment.

Control Valve

The control valve is used to close, control and connect the flow of fluids in various industries. Control valves are controlled by actuators. There are five types of actuators to control valves, which are: Manual (mechanical), electric, thermal, pneumatic and hydraulic actuators. It should be noted that control valves or control valves are designed and produced in two types with linear and rotary movement.

- ON/OFF valves (Ball Valve and Butter Fly Valve are of this type)

- Safety valve

- Isolation valve (Split valves, Single Seat valves and Knife Valve are considered isolation valves)

- Control Valves (Globe Valve and Needle Valve)

- Self-control valves or Check Valve

- Gate valve

- Diaphragm valve

- Slide valve

- Solenoid valve

- Back pressure regulating valve and Flow regulating valve

- Flush bottom valve

Solenoid Valve

This equipment adjusts the input and output of the valve by converting electrical energy into mechanical energy.

Hydraulic Valve

The hydraulic valve is responsible for controlling the flow rate and hydraulic pressure.

Pneumatic Care Unit

This device cleans the inlet air of pneumatic systems to take care of the system and equipment.

Pneumatic Valve

Control of flow and pressure in pneumatic systems is done by this tool.

Interface circuits

Interface circuits are responsible for processing, converting or amplifying signals.

Detector

Detectors are equipment that are used to show the presence or absence of a substance in the environment. One of the most important detectors in industries are gas detectors, which are used to increase safety and prevent explosions in industrial environments. take

Recorder

Recorders or data loggers are instruments used to store information and measured values in the industry.

In what environments are instrumentation equipment used?

Instrumentation equipment is one of the most important and mandatory tools in industries, without which it would be possible to control and optimize the processes. As it was said, by using instruments, vital parameters such as pressure, temperature and flow in metal melting furnaces. , oil and gas transmission lines and petrochemical distillation columns measure.

Instrumentation equipment is used in the following environments:

- Instrumentation equipment in the steel industry

- Instrumentation equipment in the oil industry

- Instrumentation equipment for oil and gas

- Industrial electrical instrumentation

- Conveyor instrumentation equipment

- And...

There are different types of instrumentation equipment, each of which has different applications. These equipments are used in various industries such as oil, gas, petrochemical, etc., for this reason, special attention should be paid to their quality. When buying precision instruments, you should pay attention to points such as the type of brand, product authenticity, quality and authenticity of the precision instrument store.

The use of precision instrument equipment in industrial environments, with its precise performance, increases productivity, quality and security in industries. To buy this equipment, be sure to use reputable brands and well-known sellers.

You can contact our consultants at parsa the ex proof to purchase precision instruments and explosion-proof equipment.

Persian language support Phone: +98935155608

English and Arabic language support WhatsApp: 00971568410575

English and Arabic language support telegram: +16026522982